Start of the DFG project Assembly process-oriented tolerance management based on virtual computer-aided engineering tools

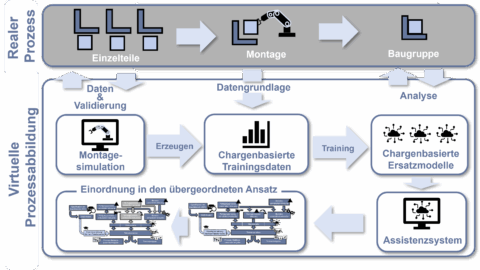

Conventional tolerance management aims to limit variations of components to a degree that guarantees the function of the product. Frequently, aspects such as manufacturability, assemblability, and influences of operation are not taken into account. As a result, variations that lead to assembly problems or variations due to wear are detected late in the product life cycle, which may cause costly and time-consuming iterations. Process-oriented tolerance management attempts to address this problem by already considering aspects of manufacturing, assembly, and operation in the tolerancing process during product development. For this purpose, the DFG-research group FOR 2271 “process-oriented tolerance management based on virtual computer-aided engineering tools” investigated methods of holistic tolerance management. The information was generated experimentally and simulatively and was used for metamodel training. The goal was to be able to provide information from production and operation right from the development stage. Thanks to the interdisciplinary composition of the research group, it was possible to develop a holistic procedure for process-oriented tolerance allocation. So far, this approach has given little consideration to the assembly process. This is particularly due to the high complexity of assembly processes and their costly mechanical requirements. Within the new knowledge transfer project “Assembly process-oriented tolerance management based on virtual computer-aided engineering tools“ (project number 548536423), assembly is now being integrated into the holistic approach. The project is being carried out in collaboration with a German automobile manufacturer, which is contributing large amounts of data from real assembly processes as well as experience in the field of assembly technology to the project. A particular focus of the project is the batch-based processing of real assembly data. This is intended to minimize the necessary additional effort due to the assembly process-oriented tolerance management. Furthermore, the project focuses on the investigation of assembly processes without a positioning device (e.g. assembly of an adhesive joint by robot arm). At the end of the project, the users should be able to predict variations in batch-based assembly processes, triggered by individual part variations or assembly parameters, and to initiate targeted measures ensuring product quality.