Lightweight Design Center

Material characterization and -modeling for crash-adapted lightweight designs

To ensure crash properties in the construction and design of vehicles, the use of computer-aided design methods has already established itself in the early phases of product development. In order to guarantee a high quality of the results of the simulation methods used, the material models must meet the high requirements that the calculation of the structures, which are often anisotropic and subjected to high strain rates in the event of a crash, entails.

To ensure crash properties in the construction and design of vehicles, the use of computer-aided design methods has already established itself in the early phases of product development. In order to guarantee a high quality of the results of the simulation methods used, the material models must meet the high requirements that the calculation of the structures, which are often anisotropic and subjected to high strain rates in the event of a crash, entails.

The selection of suitable material models and the experimental determination of the strain rate- and temperature dependent material parameters is part of the work of the lightweight design group at the Chair of Engineering Design at FAU. The simulation results obtained can be validated with crash tests at component level.

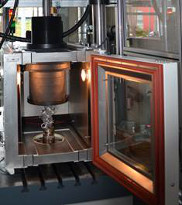

Servo-hydraulic high-speed test rig

With the Zwick HTM 5020 servohydraulic high-speed testing system, tensile and puncture tests can be carried out with up to 50 kN load and 20 m/s haul-off speed. This corresponds to achievable strain rates of up to 1000 s-1. For force evaluation of the tests lasting only a few milliseconds, the input signals are recorded and provided at high frequencies of up to 8 MHz. In combination with the GOM Aramis HHS optical evaluation technology, precise stress-strain curves can be created, which form the basis for parameter optimization of material models.

With the Zwick HTM 5020 servohydraulic high-speed testing system, tensile and puncture tests can be carried out with up to 50 kN load and 20 m/s haul-off speed. This corresponds to achievable strain rates of up to 1000 s-1. For force evaluation of the tests lasting only a few milliseconds, the input signals are recorded and provided at high frequencies of up to 8 MHz. In combination with the GOM Aramis HHS optical evaluation technology, precise stress-strain curves can be created, which form the basis for parameter optimization of material models.

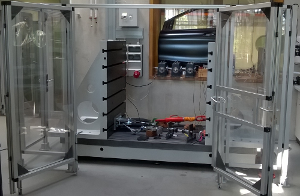

Servo-hydraulic pulser HCT25

A servo-hydraulic pulser is available for research into the fatigue behaviour of fibre-reinforced lightweight materials. It can be used to carry out cyclical tests with axial loads up to 25 kN, tor-ques up to 250 Nm and test frequencies up to 30 Hz. An additional temperature control in the range between -30 °C and 150 °C also opens up the possibility of investigating thermomechani-cal fatigue.

A servo-hydraulic pulser is available for research into the fatigue behaviour of fibre-reinforced lightweight materials. It can be used to carry out cyclical tests with axial loads up to 25 kN, tor-ques up to 250 Nm and test frequencies up to 30 Hz. An additional temperature control in the range between -30 °C and 150 °C also opens up the possibility of investigating thermomechani-cal fatigue.

Temperature chamber

An integrated temperature chamber allows tests from -60° to 150 °C. This allows the test conditions to be adapted to subsequent use and temperature-dependent material behavior to be investigated.

An integrated temperature chamber allows tests from -60° to 150 °C. This allows the test conditions to be adapted to subsequent use and temperature-dependent material behavior to be investigated.

Stereoscopic camera system

To ensure accurate, non-contact strain measurement, the ARAMIS HHS and ARAMIS 4M sys-tems are two powerful camera systems from GOM that can be used on both the high-speed testing machine and the pulser. Recording rates of around 100 000 Hz can be achieved for the observation of high-speed tensile tests, and up to 120 Hz for the scanning of cyclic tests. By means of digital image correlation the occurring strain is determined locally and compared with simulation results.

To ensure accurate, non-contact strain measurement, the ARAMIS HHS and ARAMIS 4M sys-tems are two powerful camera systems from GOM that can be used on both the high-speed testing machine and the pulser. Recording rates of around 100 000 Hz can be achieved for the observation of high-speed tensile tests, and up to 120 Hz for the scanning of cyclic tests. By means of digital image correlation the occurring strain is determined locally and compared with simulation results.

Drop tower

A drop tower is available for component testing and validation of material models. It can be used for impactor tests at impact speeds of up to 5 m/s. The maximum transferable energy is 200 J. The fracture patterns and deformations of the test and simulation can then be compared and, if necessary, adjusted. This ensures that the material data determined from tensile tests on test specimens also provide correct results at component level.

A drop tower is available for component testing and validation of material models. It can be used for impactor tests at impact speeds of up to 5 m/s. The maximum transferable energy is 200 J. The fracture patterns and deformations of the test and simulation can then be compared and, if necessary, adjusted. This ensures that the material data determined from tensile tests on test specimens also provide correct results at component level.

Stiffness test rig – “Bärenfels”

The “Bärenfels” stiffness test rig is usable for component and assembly tests. Due to the large test dimensions of 1300 x 1250 x 1000 mm, tests can also be carried out on entire assemblies, e.g. the sagging of a car door. With the aid of a hydraulic cylinder and deflection rollers, a load of up to 100 kN can be applied in almost any orientation. The modular design also allows compo-nent-specific test setups to be implemented very quickly and easily.

The “Bärenfels” stiffness test rig is usable for component and assembly tests. Due to the large test dimensions of 1300 x 1250 x 1000 mm, tests can also be carried out on entire assemblies, e.g. the sagging of a car door. With the aid of a hydraulic cylinder and deflection rollers, a load of up to 100 kN can be applied in almost any orientation. The modular design also allows compo-nent-specific test setups to be implemented very quickly and easily.