Additive Manufacturing Laboratory

Additive Manufacturing Laboratory at KTmfk

In recent years, Additive Manufacturing has developed from an interesting but inefficient technology to one of the most promising key technologies in modern manufacturing. The various manufacturing processes show their strengths especially in the manufacture of individualized parts with complex geometries and internal structures at batch size-independent manufacturing costs. Due to its great potential, Additive Manufacturing is an integral part of the current research activities at the KTmfk and is profitably used in various research projects for the Rapid Prototyping, Rapid Tooling and Rapid Manufacturing.

Stratasys F370

The Fused Layer Modeling (FLM)-printer Stratasys F370 with its closed chamber and stable process control enables the production of high-quality components from high strength and flexible materials such as ABS, ASA or TPU. The support structures, which are necessary to realize overhangs and undercuts, are printed from water-soluble support material, so that they don’t have to be mechanically removed. Instead, they are subsequently removed at temperatures between 50 – 80 °C in the cleaning apparatus SCA 3600. Thus, this enables the production of entire, as-built assemblies in one single manufacturing step.

The Fused Layer Modeling (FLM)-printer Stratasys F370 with its closed chamber and stable process control enables the production of high-quality components from high strength and flexible materials such as ABS, ASA or TPU. The support structures, which are necessary to realize overhangs and undercuts, are printed from water-soluble support material, so that they don’t have to be mechanically removed. Instead, they are subsequently removed at temperatures between 50 – 80 °C in the cleaning apparatus SCA 3600. Thus, this enables the production of entire, as-built assemblies in one single manufacturing step.

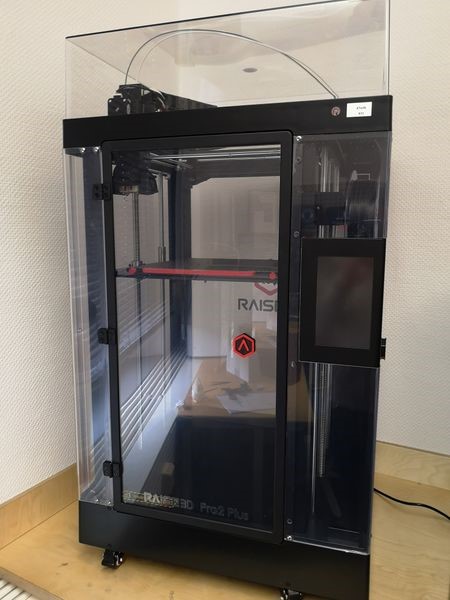

3D-Printer Raise3D Pro2 Plus

With Raise3D Pro2 Plus the KTmfk’s Additive Manufacturing Laboratory is extended by a further 3D printer. This is a 3D Fused Deposition Modeling Printer, which has a heatable building plate (up to 110°C) and an build space of 305 x 305 x 610 mm. Because of the built-in dual extruder, both building material and water-soluble support material can be used simultaneously to create overhangs and undercuts. These support structures can then be washed out with a special solvent at temperatures between 50 – 80°C using the SCA 3600 wash-out station. This enables the production of movable, assembly-free assemblies. Typical thermoplastic materials (PLA, ABS, TPU, etc.) as well as short fibre reinforced carbon filament are available.

With Raise3D Pro2 Plus the KTmfk’s Additive Manufacturing Laboratory is extended by a further 3D printer. This is a 3D Fused Deposition Modeling Printer, which has a heatable building plate (up to 110°C) and an build space of 305 x 305 x 610 mm. Because of the built-in dual extruder, both building material and water-soluble support material can be used simultaneously to create overhangs and undercuts. These support structures can then be washed out with a special solvent at temperatures between 50 – 80°C using the SCA 3600 wash-out station. This enables the production of movable, assembly-free assemblies. Typical thermoplastic materials (PLA, ABS, TPU, etc.) as well as short fibre reinforced carbon filament are available.

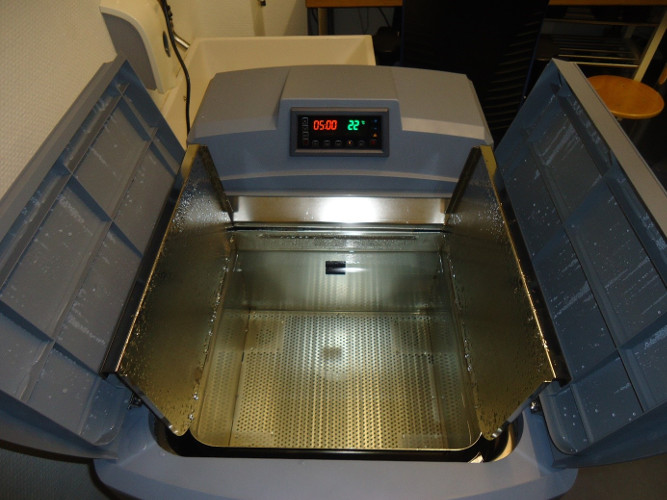

Support Cleaning Apparatus SCA3600

Not every component geometry can be easily additively produced with the 3D printing process Fused-Deposition-Modeling (FDM). Often support structures are required, for example, to realize the printing of parts with overhangs or undercuts. One possibility is to print the support structures from the same material as the building material and to remove them mechanically afterwards. If the FDM printer has a dual extruder, the printing material and the support material can be different. For 3D printing of ABS components with the help of the FDM printer Stratasys F370 and the Raise3D Pro2 Plus, the water-soluble material QSR is used as support material, which can be subsequently washed out. The SCA 3600 wash-out station from PADT (Support Cleaning Appartus 3600) is used to dissolve the support material of additive-manufactured components using a heated water bath to which cleaning solution is added. The temperature range can vary between 50 – 85°C (approx. 70°C is recommended for ABS).

Not every component geometry can be easily additively produced with the 3D printing process Fused-Deposition-Modeling (FDM). Often support structures are required, for example, to realize the printing of parts with overhangs or undercuts. One possibility is to print the support structures from the same material as the building material and to remove them mechanically afterwards. If the FDM printer has a dual extruder, the printing material and the support material can be different. For 3D printing of ABS components with the help of the FDM printer Stratasys F370 and the Raise3D Pro2 Plus, the water-soluble material QSR is used as support material, which can be subsequently washed out. The SCA 3600 wash-out station from PADT (Support Cleaning Appartus 3600) is used to dissolve the support material of additive-manufactured components using a heated water bath to which cleaning solution is added. The temperature range can vary between 50 – 85°C (approx. 70°C is recommended for ABS).