Completion of the DFG project „Continuous analysis of variations during the design of endless-fiber reinforced composite structure assemblies“

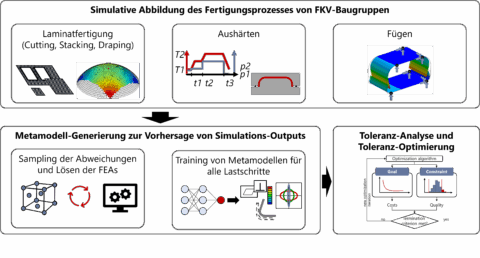

The consideration of variations and their functional restriction during the design of a product is an important task of tolerance management. Endless-fiber reinforced plastics (FRP), which are increasingly used due to their high lightweight potential, increase the complexity of this task due to their high number of design parameters. Geometric variations and residual stresses of individual components, which result from variations in the laminate design parameters, accumulate in the assembly and thus the final product. Additional residual stresses can occur in the assembly due to the assembly process, which have an impact on the supportable loads of the assembly. In the DFG project “Continuous analysis of variations during the design of endless-fiber reinforced composite structures assemblies” (project number 389616685), a method was developed for the consistent consideration of laminate deviations and their effects up to the utilization phase of the assembly. The method enables product developers to identify potential problems during the design of the composite structure and to take appropriate targeted countermeasures. Various parameters can be taken into account, such as material variations, fiber angle variations due to draping and manual work, or thickness variations. These not only influence the structural behavior, but also the deformation behavior during the curing of the individual parts. With the help of metamodels, the effects of these variations on the individual parts and on the assembly after the joining process can be predicted up to the utilization phase. This allows deformations and failure criteria to be examined at all process steps and the laminate parameters to be restricted with the help of a tolerance optimization so that the functional and failure-critical boundary conditions can be met.