Start of the DFG Project on Dynamic Tolerance Allocation in Production Ramp-Up

High-quality manufactured products are not only a key customer requirement but also a decisive factor for economic success in international competition. This is especially for delicate high-precision products. Since manufacturing operates at the limits of technological feasibility, tolerance allocation plays a decisive role here, as tolerances that are too tight lead to significantly increased manufacturing costs or cannot be manufactured reliably. In contrast, tolerances that are too wide endanger the functional performance of a product. However, conventional statistical approaches, such as those used in tolerance analysis and synthesis, cannot be readily applied to the virtual validation of high-precision components in production ramp-up, as these require settled processes.

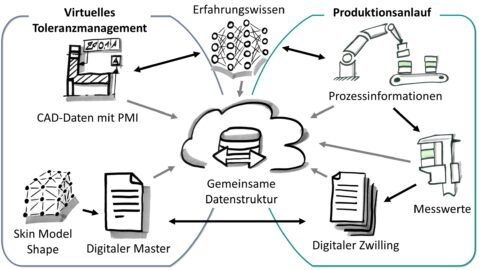

Therefore, the research project will investigate methods for dynamic tolerance allocation in product development and quality control. The aim is to integrate current information and measurement data from manufacturing and assembly, taking into account their uncertainties, through the use of digital twins for the product and the production system. The focus is on the start of production, with the aim of not only increasing product quality but also improving the first-pass yield.

In addition, methods for short-cycle improvement of product quality are being researched and implemented in a prototype demonstrator assembly. This work will result in a holistic approach to quality improvement that includes situation-dependent strategies consisting of a combination of tolerance adjustment and quality control strategies.

Upon completion of the research project, transferable methods will have been developed and validated so that their suitability for different problems can be evaluated. In order to carry out the research project, expertise from two fields of research must be combined. On the one hand, knowledge of the holistic design and evaluation of production systems is required. On the other hand, experience in the field of statistical tolerance simulation is necessary. For this reason, the project is being carried out in cooperation with the wbk Institute of Production Science at KIT.