Tactile and Optical Surface Measurement Devices

Visualization of the surface

In order to supplement the tests on layer characterization, we use optical and touch-sensitive methods at the Chair of Engineering Design, which make our test results visible. Thus, tendencies in the development of layers can also be communicated quickly and clearly in popular science.

In order to supplement the tests on layer characterization, we use optical and touch-sensitive methods at the Chair of Engineering Design, which make our test results visible. Thus, tendencies in the development of layers can also be communicated quickly and clearly in popular science.

Surface profiler

With the S3P stylus instrument from Mahr, the KTmfk with the PRK feed unit and the RFHTB micro-touch probe system has a robust instrument for tactile determination of standardized surface roughness parameters. A sensitively mounted probe tip traverses the object to be tested along a measuring path in a straight line at a constant speed, whereby the mechanical deflections are converted into digital values by the surface structure and output as a profile. This profile serves as a basis for the calculation of various parameters. Furthermore, wear traces after tribological tests can be well represented with this device.

With the S3P stylus instrument from Mahr, the KTmfk with the PRK feed unit and the RFHTB micro-touch probe system has a robust instrument for tactile determination of standardized surface roughness parameters. A sensitively mounted probe tip traverses the object to be tested along a measuring path in a straight line at a constant speed, whereby the mechanical deflections are converted into digital values by the surface structure and output as a profile. This profile serves as a basis for the calculation of various parameters. Furthermore, wear traces after tribological tests can be well represented with this device.

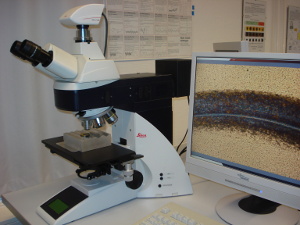

Digital light microscope

The proven LEICA DM4000 M materials microscope is used in combination with modern measuring software from LEICA for a wide range of tasks at the Chair. Six objectives from 2.5x to 100x are available for the documentation of surface characteristics before and after the various sample preparation processes and the results of the surface characterization methods performed.

The proven LEICA DM4000 M materials microscope is used in combination with modern measuring software from LEICA for a wide range of tasks at the Chair. Six objectives from 2.5x to 100x are available for the documentation of surface characteristics before and after the various sample preparation processes and the results of the surface characterization methods performed.

Laser scanning microscope

Together with the Chair of Production Engineering, the KTmfk operates the confocal laser scanning microscope VK-X200 from Keyence with a motorized X-Y object table. By using laser light source and white light source it is possible to obtain three images: A colour image with excellent depth of field, a laser intensity image and an image with height information which can be combined into an omnifocal image using analysis software. This provides a powerful, non-contact 3D measuring system for precise profile and roughness measurements, even on curved surfaces, which makes it possible to evaluate the raceway topology, especially after tribological tests on high-performance materials.

Together with the Chair of Production Engineering, the KTmfk operates the confocal laser scanning microscope VK-X200 from Keyence with a motorized X-Y object table. By using laser light source and white light source it is possible to obtain three images: A colour image with excellent depth of field, a laser intensity image and an image with height information which can be combined into an omnifocal image using analysis software. This provides a powerful, non-contact 3D measuring system for precise profile and roughness measurements, even on curved surfaces, which makes it possible to evaluate the raceway topology, especially after tribological tests on high-performance materials.

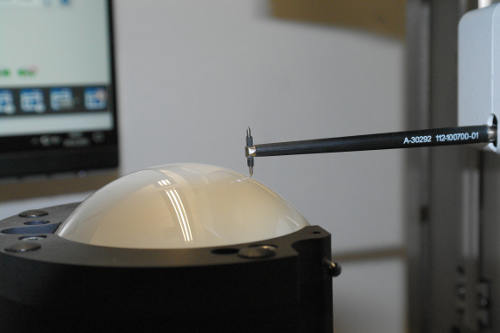

Form Talysurf PGI NOVUS, by Taylor Hobson

With the Form Talysurf PGI NOVUS from Taylor Hobson, the KTmfk can call a high-precision tactile probe system its own. Surface properties, contours and 3D topographies can be determined, resolved with an accuracy of up to 0.2 nm and optionally evaluated automatically. The combination of a dual bias probe system and the advanced Metrology 4.0 analysis software enables intuitive, repeatable and precise measurement and analysis of surface texture and profile measurements in normal and reverse directions. In addition to the excellent accuracy, various measurement concepts and publishing functions are available on the software side to prepare and display the topological results in a user-friendly manner.

With the Form Talysurf PGI NOVUS from Taylor Hobson, the KTmfk can call a high-precision tactile probe system its own. Surface properties, contours and 3D topographies can be determined, resolved with an accuracy of up to 0.2 nm and optionally evaluated automatically. The combination of a dual bias probe system and the advanced Metrology 4.0 analysis software enables intuitive, repeatable and precise measurement and analysis of surface texture and profile measurements in normal and reverse directions. In addition to the excellent accuracy, various measurement concepts and publishing functions are available on the software side to prepare and display the topological results in a user-friendly manner.