Laboratory for mechanical-physical surface characterization

Devices for mechanical-physical surface characterization

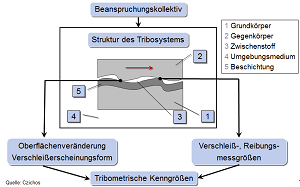

Coating systems as separate design elements enable the available substrate materials to be adapted to ever new requirements in terms of wear, friction and lubricant savings. With a specific selection of suitable test equipment, coating systems developed at the KTmfk as well as coated specimens and components of our external partners are comprehensively tested mechanically, physically and tribologically with regard to application-relevant points in order to define the optimum operating conditions of the design and to optimize the coatings for the respective tribological system requested.

Coating systems as separate design elements enable the available substrate materials to be adapted to ever new requirements in terms of wear, friction and lubricant savings. With a specific selection of suitable test equipment, coating systems developed at the KTmfk as well as coated specimens and components of our external partners are comprehensively tested mechanically, physically and tribologically with regard to application-relevant points in order to define the optimum operating conditions of the design and to optimize the coatings for the respective tribological system requested.

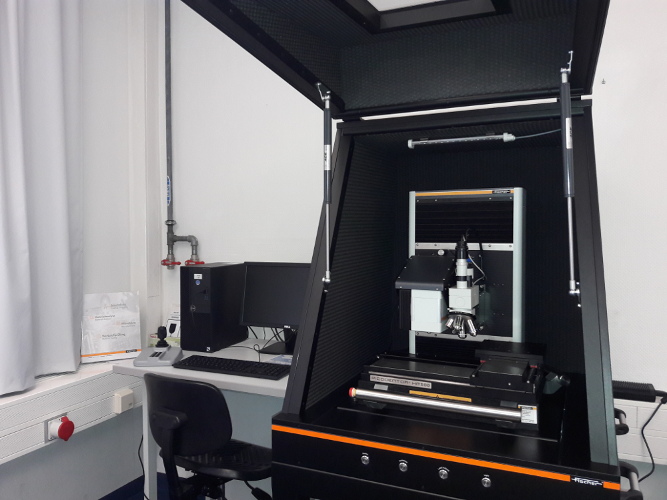

Indentation measuring device PICODENTOR HM500

The indentation measuring device PICODENTOR HM500 from HELMUT FISCHER, which works according to the load-indentation-depth-method, allows precise hardness and elasticity measurements on thin coatings and modified material surfaces in the nanometer range. In addition to the instrumented indentation test according to DIN EN ISO 14577 1 and ASTM E 2546 in microscale range, the characteristics can also be determined dependent on force and depth by stepwise loading and unloading measurements (ESP measurements).

The indentation measuring device PICODENTOR HM500 from HELMUT FISCHER, which works according to the load-indentation-depth-method, allows precise hardness and elasticity measurements on thin coatings and modified material surfaces in the nanometer range. In addition to the instrumented indentation test according to DIN EN ISO 14577 1 and ASTM E 2546 in microscale range, the characteristics can also be determined dependent on force and depth by stepwise loading and unloading measurements (ESP measurements).

Hardness tester DuraJet 10G5

The modern, motor-driven hardness tester DuraJet 10 from EMCO-TEST Prüfmaschinen GmbH is available for testing the layer adhesion with the Rockwell indentation test according to DIN EN ISO 26443. The approach of the test head to the test object from above, together with a special specimen holder, also allows the testing of round components. The LEICA DM4000 M measuring microscope is used for evaluation and documentation, including changes to the surface at the edges with regard to cracks and flaking.

The modern, motor-driven hardness tester DuraJet 10 from EMCO-TEST Prüfmaschinen GmbH is available for testing the layer adhesion with the Rockwell indentation test according to DIN EN ISO 26443. The approach of the test head to the test object from above, together with a special specimen holder, also allows the testing of round components. The LEICA DM4000 M measuring microscope is used for evaluation and documentation, including changes to the surface at the edges with regard to cracks and flaking.

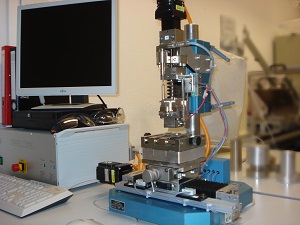

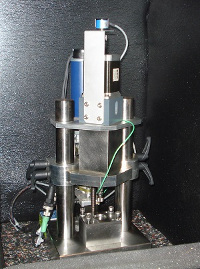

Scratch-Tester

Another method of determining the adhesion of thin layers on a substrate or their scratch resistance is available at the KTmfk with the scratch tester RTG-2, an own construction of the Chair. With variable control for load application, velocity and rise time, a diamond with Rockwell C geometry is drawn linearly over the surface to be tested, recording the measured data at a frequency of up to 8 Hz, enabling quantitative evaluation of the tests. The qualitative evaluation of the generated tracks is carried out with the LEICA DM4000 M measuring microscope. The scratch tester also allows hardness tests, for which two indenters with steel balls are available.

Another method of determining the adhesion of thin layers on a substrate or their scratch resistance is available at the KTmfk with the scratch tester RTG-2, an own construction of the Chair. With variable control for load application, velocity and rise time, a diamond with Rockwell C geometry is drawn linearly over the surface to be tested, recording the measured data at a frequency of up to 8 Hz, enabling quantitative evaluation of the tests. The qualitative evaluation of the generated tracks is carried out with the LEICA DM4000 M measuring microscope. The scratch tester also allows hardness tests, for which two indenters with steel balls are available.

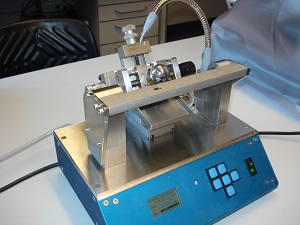

Spherical grinding device

With the spherical grinding device KSG-2, the layer thickness of the samples to be examined can be determined in a fast and inexpensive way by generating a spherical grinding on a flat sample surface with subsequent optical measurement on the measuring microscope.

With the spherical grinding device KSG-2, the layer thickness of the samples to be examined can be determined in a fast and inexpensive way by generating a spherical grinding on a flat sample surface with subsequent optical measurement on the measuring microscope.

Impact-Tester

The impact tester IT-1000/100, which was developed at the KTmfk, can be used to investigate the fatigue strength and wear resistance of coating systems under dynamic load stress. A fixed ball with forces from 200 to a maximum of 1000 N and a frequency of up to 100 Hz is hammered onto the specimen surface. The cracking or layer delamination observed under the microscope allows conclusions to be drawn about the dynamic strength of a layer-substrate composite.

The impact tester IT-1000/100, which was developed at the KTmfk, can be used to investigate the fatigue strength and wear resistance of coating systems under dynamic load stress. A fixed ball with forces from 200 to a maximum of 1000 N and a frequency of up to 100 Hz is hammered onto the specimen surface. The cracking or layer delamination observed under the microscope allows conclusions to be drawn about the dynamic strength of a layer-substrate composite.

Contact angle meter

The Krüss G10 contact angle meter with modern analysis software is used to determine the free surface energy, a measurement of the wetting capacity of surfaces and their tendency to adhesion, which is particularly interesting in connection with the development of low-lubricant machine elements. For this purpose, test series with different test liquids of known surface tension are carried out, from the wetting angle of which the surface tension of the tested sample can be determined mathematically.

The Krüss G10 contact angle meter with modern analysis software is used to determine the free surface energy, a measurement of the wetting capacity of surfaces and their tendency to adhesion, which is particularly interesting in connection with the development of low-lubricant machine elements. For this purpose, test series with different test liquids of known surface tension are carried out, from the wetting angle of which the surface tension of the tested sample can be determined mathematically.