Digital Engineering

Digital Engineering at the KTmfk

The Digital Engineering group is concerned with digital methods and tools as well as the holistic use and evaluation of data in virtual product development. The commitment of the group is divided into the areas “Machine Learning”, “Systems Engineering” and “Virtual Reality (VR) and Augmented Reality (AR) in Product Development”.

Machine Learning

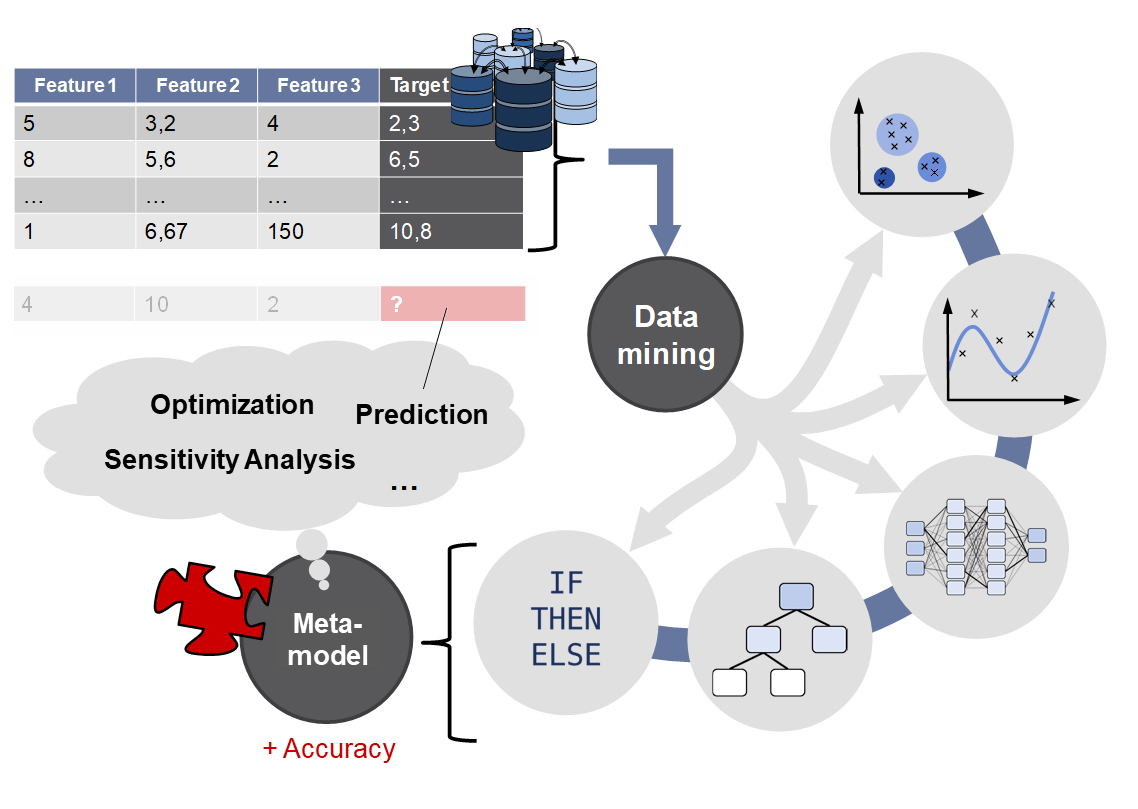

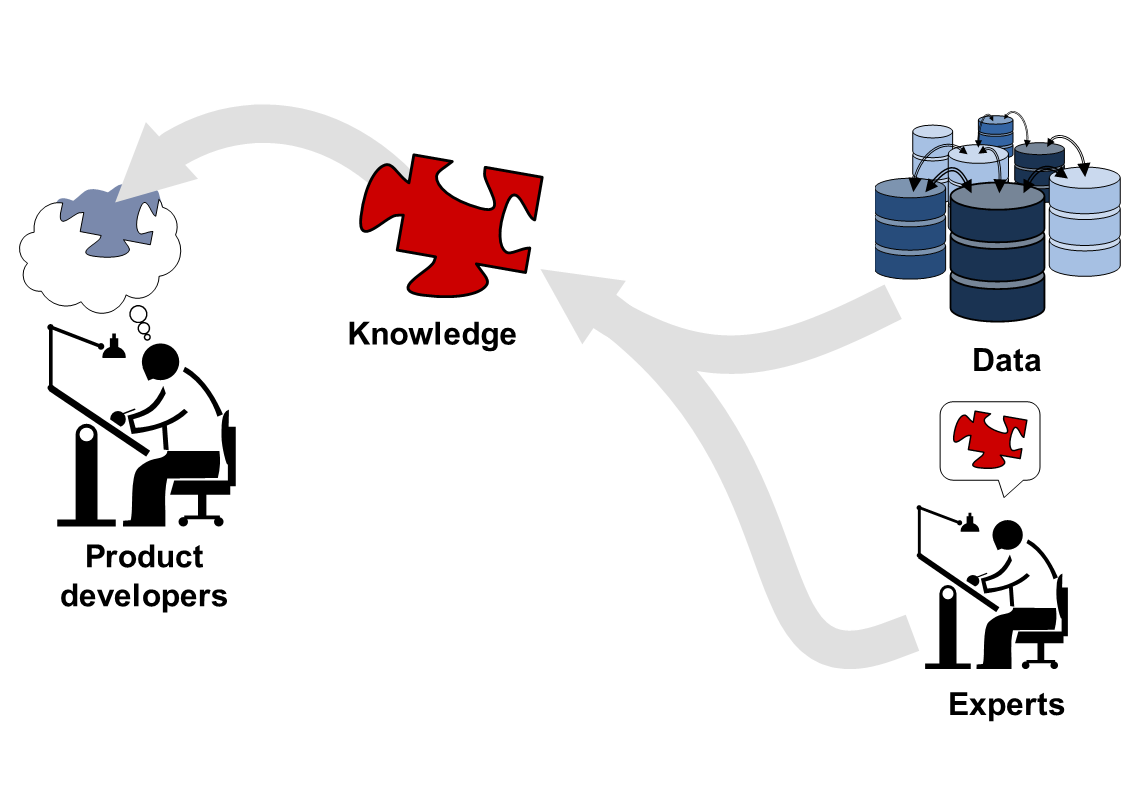

Against the background of knowledge-based design, the KTmfk recognized the enormous potential of data evaluation within the product development process at an early stage. The group uses machine learning methods to generate knowledge from data of the entire product life cycle. These are in turn intended to provide the product developer with support for a wide range of activities in the context of virtual product development and thus form an essential component of digital engineering.

Against the background of knowledge-based design, the KTmfk recognized the enormous potential of data evaluation within the product development process at an early stage. The group uses machine learning methods to generate knowledge from data of the entire product life cycle. These are in turn intended to provide the product developer with support for a wide range of activities in the context of virtual product development and thus form an essential component of digital engineering.

Within Machine Learning, the group focuses primarily on data and text mining methods. Here, the generation of ontologies for the basic structure of knowledge-based systems in product development is being researched. Specifically, this involves mapping the product and function structure in a machine-readable format in order to convert it into a semantically more sophisticated representation.

In addition, self-learning, knowledge-based systems are being developed within the framework of production-oriented design, which enable existing component designs to be optimised. Data from simulation and testing are combined to create prediction models for resulting component properties.

In addition, deep learning methods are being researched to check the plausibility of FE simulations. Both data and expert knowledge are used. The models generated in this way support the product developer at an early stage in setting up simulations.

Systems Engineering

Global trends such as functional integration, individualization and interdisciplinary approaches have led to a rapid increase in product complexity. The necessary understanding of the product development process (PDP) requires new methods and approaches. The KTmfk meets these challenges with approaches from systems engineering.

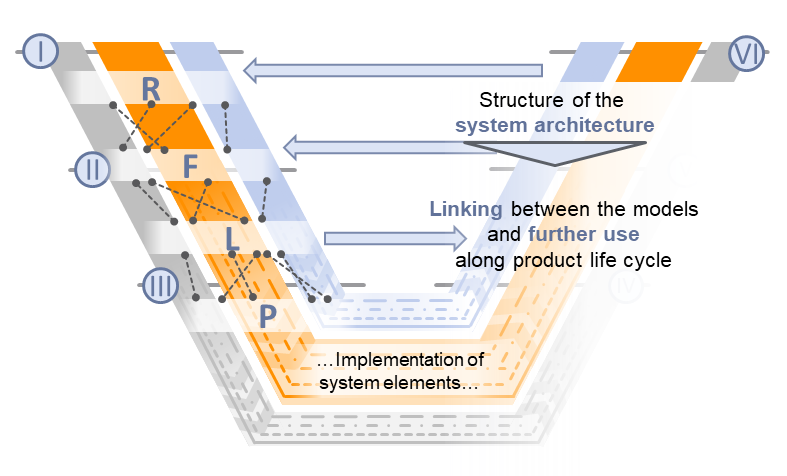

In this context, digital and continuously linked models for all phases of the PDP are developed, using the RFLP approach. It structures the PDP based on the requirements (R) via the functions (F), the logics structure (L) and the physical characteristics (P). Models are generated and linked for each of these levels. They increase traceability and help to increase transparency in the development of complex products. Consequently, the information is not stored in documents (e.g. Word, PDF), but in machine-readable system models (SysML). This approach provides interfaces for automation and enables the use of machine learning throughout the PDP. It is conceivable that, starting from a change in requirements, the necessary adaptation of the features can be concluded.

In this context, digital and continuously linked models for all phases of the PDP are developed, using the RFLP approach. It structures the PDP based on the requirements (R) via the functions (F), the logics structure (L) and the physical characteristics (P). Models are generated and linked for each of these levels. They increase traceability and help to increase transparency in the development of complex products. Consequently, the information is not stored in documents (e.g. Word, PDF), but in machine-readable system models (SysML). This approach provides interfaces for automation and enables the use of machine learning throughout the PDP. It is conceivable that, starting from a change in requirements, the necessary adaptation of the features can be concluded.

VR und AR in der Produktentwicklung

Virtual Reality and Augmented Reality are human-machine interfaces that enable computer-generated content to be perceived realistically in response to several senses. Drafts can be viewed and discussed in design reviews. In this context, on the one hand, the synthesis of product design through natural finger interaction is explored, which enables even less experienced users to quickly create initial CAD designs. On the other hand, the realistic visualization of virtual environments through eye-tracking is being researched.

Virtual Reality and Augmented Reality are human-machine interfaces that enable computer-generated content to be perceived realistically in response to several senses. Drafts can be viewed and discussed in design reviews. In this context, on the one hand, the synthesis of product design through natural finger interaction is explored, which enables even less experienced users to quickly create initial CAD designs. On the other hand, the realistic visualization of virtual environments through eye-tracking is being researched.