Rolling bearing technology

Rolling bearing technology at KTmfk

Rolling bearings are indispensable in many technical appliances used in everyday life. The importance of rolling bearings in mechanical engineering can be compared with the importance of the transistor for electronics. Rolling bearings have both guiding and supporting functions in machines, devices and vehicles of all kinds. While often unnoticed, they function reliably and in an energy-efficient manner.

For over 30 years, KTmfk has contributed to the technological and scientific progress in rolling bearing technology. We investigate rolling bearings as an independent component and in terms of interaction with the housing design. In our research projects, the processes of design, calculation and testing are closely interlinked.

Collaborations in research and industry

Thanks to close proximity to the European rolling bearing industry, KTmfk maintains successful collaborations with research institutions and industrial companies. This ensures effective knowledge transfer and the identification of new research areas.

Focus on engineering training

Our Master’s degree students study all core aspects of rolling bearing technology and gain in-depth knowledge in the courses ‘Rolling Bearing Technology’ and ‘Tribology and Surface Technology’.

Simulation

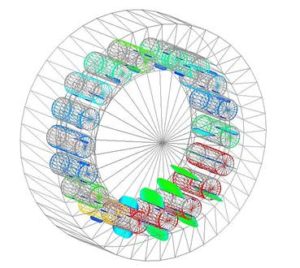

The goal of research based on simulation is to gain a systematic understanding of complex rolling bearing arrangements with regard to aspects such as dynamics and friction behaviour. We adopt different simulation approaches from the micro to the macro level.

On the micro level, we analyse individual contacts in enhanced FE simulations with regard to the lubrication conditions in EHD contacts. This is useful for designing micro structures for rolling or sliding contacts which match the mechanical load.

On the macro level, we use multibody simulations specifically adapted to rolling bearings to show the dynamics of rolling bearing components. With these simulations we can analyse the rolling bearing behaviour under high centripetal acceleration or in flexible adjacent housing designs.

Testing

Simulations must always be validated by experimental tests. There are many effects of rolling bearing arrangements that have not yet been theoretically described in a sufficiently precise manner which is why testing is indispensable in rolling bearing technology.

Experimental research at KTmfk includes the development of advanced, innovative test rigs. We use state-of-the-art CAD and FEM tools to develop draft designs into new, unique test rig designs. These test rigs are manufactured and assembled in close co-operation with FAU’s own workshops and used intensively for experimental research projects at KTmfk’s laboratories.

Current experimental projects address aspects such as friction in rolling bearings and rolling bearing behaviour under centripetal acceleration or exposure to vibrations analysis. We are also testing new lubrication and surface concepts.

You can download this information in compressed form in a flyer here.