Tribological PVD/PACVD coating systems

Tribological PVD/PACVD coating systems

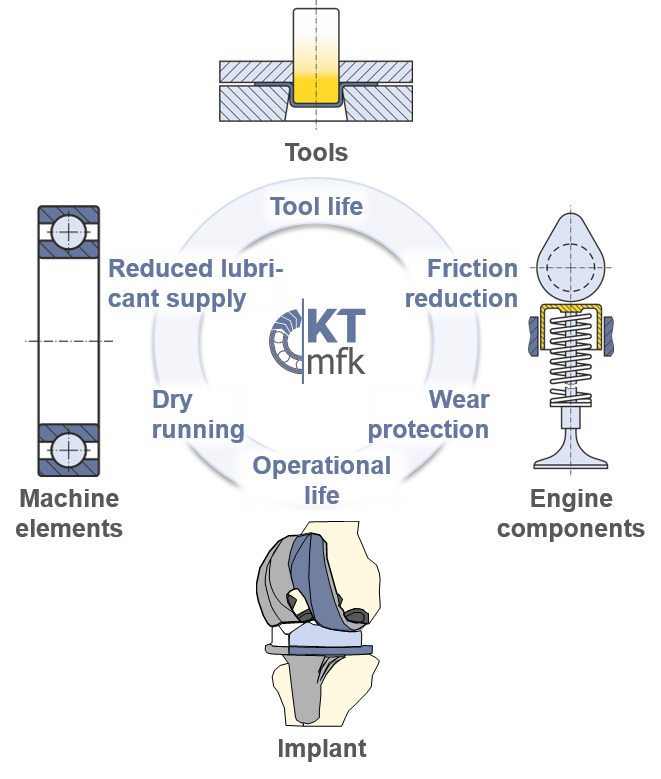

The constantly growing functional requirements for machine elements, tools and motor elements often push the basic materials used to their application limits. In the field of medical technology, the knee is one of the most highly stressed joints in humans, which often has to be replaced by an implantation of an artificial joint. With regard to friction minimization (energy efficiency) and wear protection (operational life), the increased requirements can often only be achieved through methods in micro and nanotechnology, in particular by using tribological PVD/PACVD coating systems.

KTmfk’s research activities are aimed at supporting product developers in the development of resource- and energy-efficient technical systems using tribological PVD/PACVD coating systems. The coating systems are considered as independent design elements, which require specific expertise. Research activities include

- coating development,

- tribological model and component tests,

- dimensioning principles,

- component design guidelines.

Main research topics

In the scope of application-oriented coating development and selection, a methodical approach provides the basis for coating development and the development of an improved understanding of the predominant friction and wear mechanisms. KTmfk has proven scientific competence in the fields of

- amorphous carbon coatings,

- solid lubricant coatings,

- hard coatings.

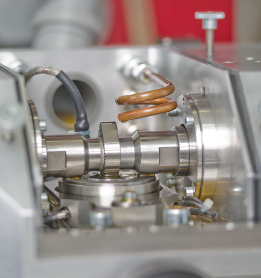

As one of the few university institutes in Germany, KTmfk is able to perform the entire process chain – from coating process via coating characterization up to component testing. In addition to a coating center with a modern, combined PVD/PACVD coating machine, a broad spectrum of testing equipment is available for this purpose. A continuous expansion of the possibilities for coating characterization characterizes the research activities of KTmfk as well as the project-specific development of test rigs, with whose help coating systems can be tested both in model tests and under realistic operating conditions. In addition to the real tests, computer-aided simulations are carried out based on continuum and fracture mechanics.

As one of the few university institutes in Germany, KTmfk is able to perform the entire process chain – from coating process via coating characterization up to component testing. In addition to a coating center with a modern, combined PVD/PACVD coating machine, a broad spectrum of testing equipment is available for this purpose. A continuous expansion of the possibilities for coating characterization characterizes the research activities of KTmfk as well as the project-specific development of test rigs, with whose help coating systems can be tested both in model tests and under realistic operating conditions. In addition to the real tests, computer-aided simulations are carried out based on continuum and fracture mechanics.

You can download this information in compressed form in a flyer here.