Start of the BFS project for the development of a time-efficient method for the determination of the performance of rolling bearings with deviations (PEDRO) in May 2024

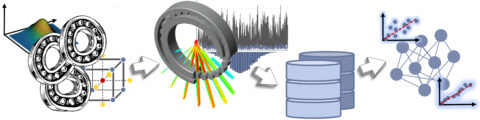

Geometric deviations in technical products are unavoidable due to process fluctuations in manufacturing and assembly processes. Geometric deviations also occur in rolling bearings, which can negatively influence the functional properties of a rolling bearing (e.g. friction or acoustics). To date, the influence of these deviations on these properties requires complex and time-consuming multi-body simulations. The large number of influencing parameters and the associated large number of calculations to be performed to determine the effect of the deviations on the functional properties impedes the definition of tolerance values. Therefore, the aim of the project is to develop a procedure that uses machine learning methods to quantify the effects of geometric deviations (tolerances) of rolling bearing components on bearing dynamics in a few seconds. By estimating the effects of tolerance specifications and allocations in a time-efficient manner, a tolerance can be defined early on in the product development process that fulfils all functional property requirements and allows the use of the most cost-effective manufacturing processes possible. In addition, the precise design of rolling bearings, considering manufacturing deviations, contributes to energy efficiency by reducing friction losses. The project PEDRO (Performance of Deviated Rolling Bearings) is funded by the BFS and takes place in co-operation with Schaeffler Technologies AG & Co. KG.