DFG- project: OptNeToL: Integrated, optimization-based parameter and tolerance design | End of project in December 2023

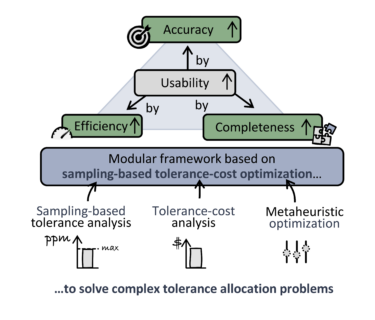

Unavoidable geometric variations are limited explicitly by geometrical and dimensional tolerances to ensure that technical systems fulfill their function despite manufacturing inaccuracies. However, in doing so, the requirements for the subsequent manufacturing and, thus, the costs are implicitly set. The method of tolerance-cost optimization manages the balancing act between low costs and high product quality by allocating all tolerance values in a cost-optimized and automated manner. However, the existing solution approaches cannot answer the practice-relevant questions comprehensively. Limitations in accuracy, completeness, efficiency, and the lack of integration into the modern product development process make it difficult to solve industrial problems, whereby hidden cost potentials mostly remain unused.

Aiming to overcome these obstacles, this two-and-a-half-year DFG project used the findings from the previous project ‘Tolerance optimization of statically under- and over-constrained assemblies’ and enhanced the method of sampling-based tolerance-cost optimization. On the one hand, the novel methods allow its use with only approximate cost information available as well as the identification of robust nominal dimensions and thus their application in early product design phases. On the other hand, the integration of form, location, and orientation tolerances, as well as machine selection and allocation strategies with machine-specific manufacturing distributions, enables its application to complex, non-linear assemblies while simultaneously considering manufacturing boundary conditions at an early stage. Harmonizing the optimization routines with variance-reducing sampling and non-conformance rate estimation techniques ensures the optimization results’ reliability. Due to the newly developed efficiency enhancement methods based on adaptive sample sizes and surrogate models, computation times can be significantly reduced without compromising the quality of the results. The final evaluation of the overall framework developed and transferred into a software prototype shows that the enhancements contribute significantly to its universal applicability. Product developers without in-depth knowledge of statistics and optimization can now determine nominal dimensions and tolerances robustly and cost optimally.